Warehouse Management Software Fundamentals Explained

Table of ContentsLittle Known Questions About Warehouse Management Software.All about Warehouse Management SoftwareMore About Warehouse Management SoftwareThings about Warehouse Management Software

You have a whole lot on the line and we want you to make your project a success, staying clear of the mistakes we see much frequently. As you begin with us, whether it be with Software Demands layouts, Contrasting, Shortlisting Vendors or obtaining that elusive Rates you need; understand that we are right here for you.Afton Production The company's 14 employees were working in routinely scheduled shifts, with morning and also mid-day breaks of 10 minutes each. Yet a number of these breaks were being stretched by added five or 10 mins. Staff members really did not have the adaptability they wanted as well as the owner was discouraged by shed performance.

The company no much longer pays workers for unapproved or excessive breaks, as well as employees are encouraged to handle their time on-the-clock more successfully. 7,280 hours conserved annually. $6,000 conserved in time and efficiency. 2 months to ROI.

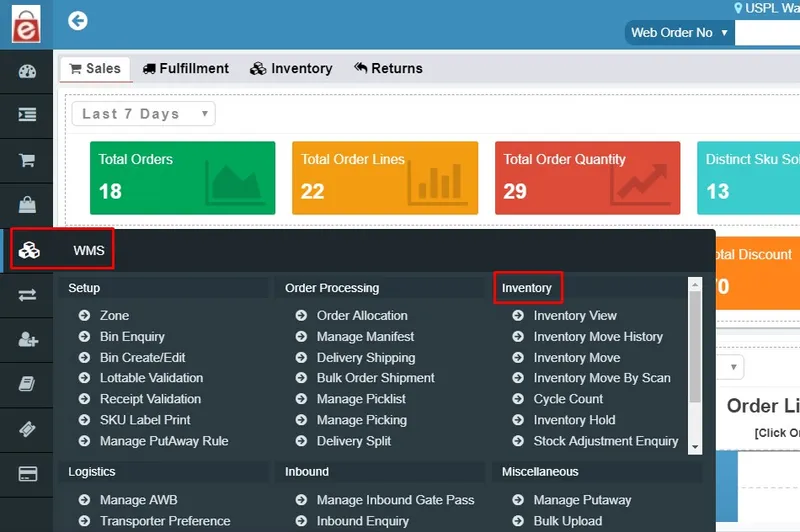

As soon as choosing operations are carried out as effectively as feasible and also any kind of needed production is executed, the next step in fulfillment is loading the order. Storage facility Monitoring software application with rule-based gratification helps in creating workflows for the most effective packaging procedures. warehouse management software. The company establishes its fulfillment guidelines, as well as the WMS applies them for optimum packing process.

The Ultimate Guide To Warehouse Management Software

Packaging is greater than positioning a solitary product in a single box, so Storage facility Management software program likewise needs the adaptability to take care of variations that emerge. A versatile software will certainly support package gratification, bill of materials fulfillment, partial deliveries, and backorder management in addition to generating reliable packing operations. Stockroom Management software application sustains many types of packaging and also aids guarantee it is executed as effectively as feasible.

Are you stressed over the losses happening in your different Storage facility operations? GoodFirms has actually noted the best Storage facility Monitoring Software application (WMS) or storehouse system that helps businesses in managing numerous warehouse procedures efficiently. Behind every effective brand stands its solid stockroom administration. Hence partnering with just the very best Warehouse Administration Solutions is highly essential for all businesses.

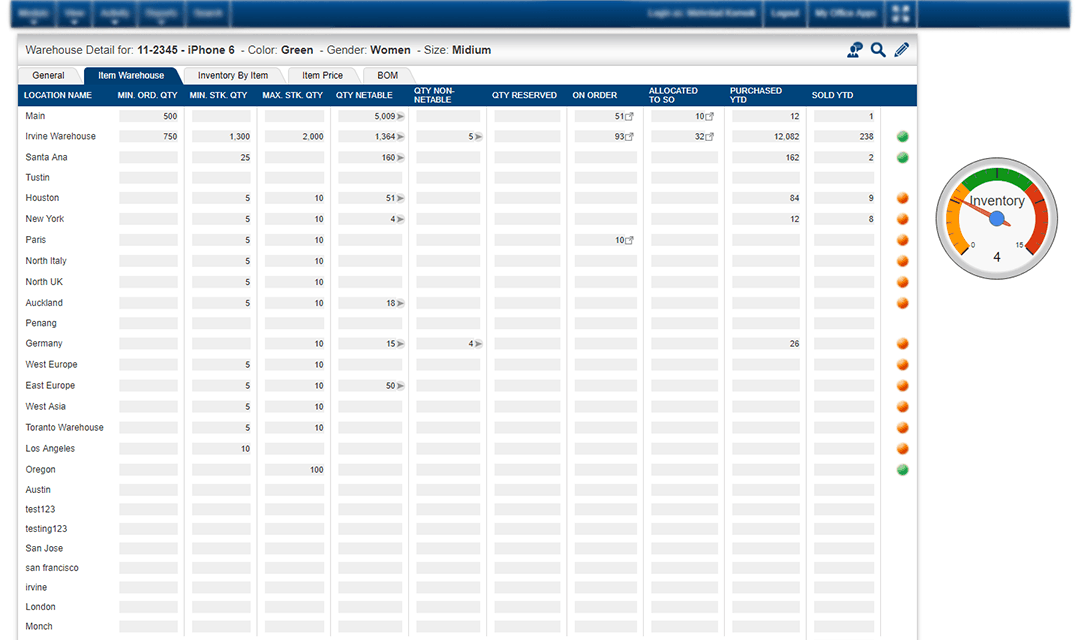

A stockroom management system (WMS) is software program and processes that enable organizations to regulate as well as carry out stockroom procedures from the time products or products enter a storehouse up until they vacate. Operations in a storage facility consist of stock administration, selecting processes and auditing. As an example, a WMS can give presence right into an organization's supply at any type of time and also location, whether in a center or en route. warehouse management software.

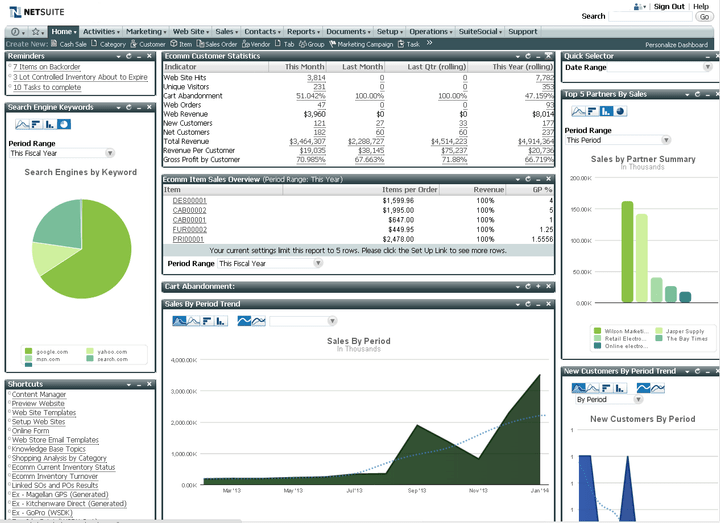

A WMS is often used together with or integrated with a transport monitoring system (TMS) or a supply administration system. Content Proceeds Below Storage facility administration systems come in a selection of types and execution techniques, and the kind typically relies on the size and also nature of the organization. They can be stand-alone systems or modules in a larger venture resource planning (ERP) system more info here or supply chain execution collection.

Some little companies might use an easy series of paper copy papers or spreadsheet data, however a lot of larger companies-- from little to medium-sized services (SMBs) to venture firms-- usage facility WMS software application. Some WMS arrangements are developed especially for the dimension of the company, and also many suppliers have versions of WMS products that can scale to various business dimensions.

The Of Warehouse Management Software

The WMS develops bin slotting that takes full advantage of storage room and also accounts for variations in seasonal inventory., which makes it possible for using sophisticated tracking systems, including radio-frequency recognition (RFID), automatic recognition and data capture (AIDC) and also barcode scanners to see to it that items can be located easily when they require to move.

, including zone picking, wave picking and also batch selecting. Stockroom workers can likewise use whole lot zoning and job interleaving functions to assist the pick-and-pack jobs in the most efficient more info here way., which enables the WMS to send out bills-of-lading (B/L) in advance of the delivery, generate packing lists and billings for the shipment and also send advancement shipment notifications to recipients.

Not known Facts About Warehouse Management Software

Such IoT information can incorporate into a WMS to help manage directing of the products from the pick-up point to the end point. This assimilation makes it possible for organizations to create pull-based supply chains, instead than push-based supply chains. warehouse management software. Pull-based supply chains are driven by consumer demand, which enables the company much more flexibility and also responsiveness, while a push-based supply chain is driven by long-term estimates of customer demand.